WSL Model Wire Drawing Machine for Nail Making

The pulley-type wire drawing machine, also known as the dry wire drawing machine, is designed to draw 6.5mm steel wire down to target diameters such as 5.8, 5.0, 4.5, 4.1, 3.7, 3.4, 3.1, 2.8, 2.5, 2.2, and 2.0mm.

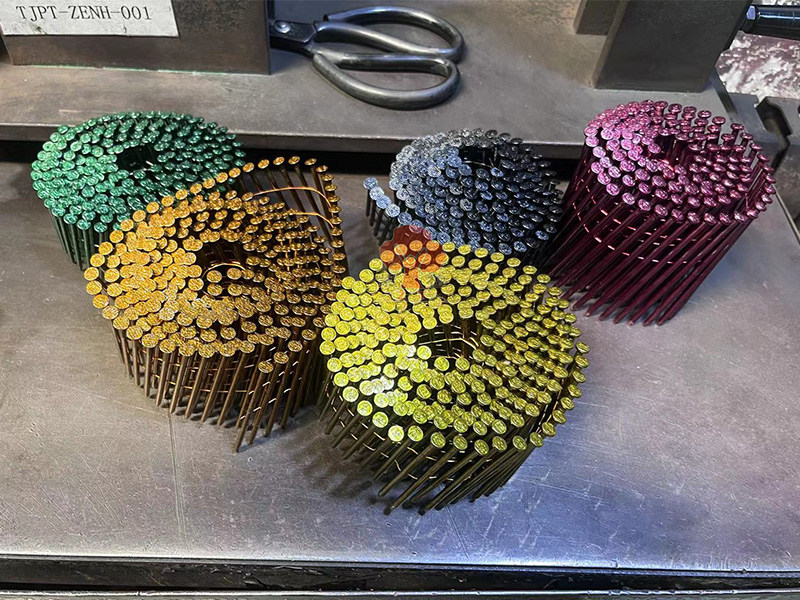

This drawing equipment produces cold-drawn wires with high precision and consistent diameter for manufacturing various nail products such as wire nails, coil nails, D-type nails, and double-headed nails and is an indispensable core link in the nail making process.

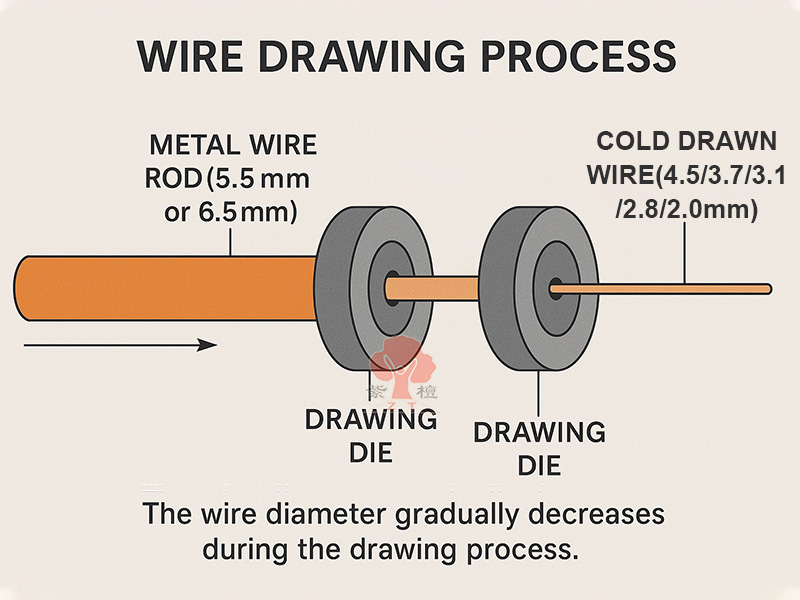

Working Principle of Wire Drawing Machine

The basic working principle of wire drawing machine is to reduce the diameter of a metal wire rod—typically 6.5mm or 5.5mm—by pulling it through a series of drawing dies with gradually smaller apertures. This process, driven by continuous tension, stretches the wire while increasing its length until the desired diameter is achieved.

Spare Parts for Wire Drawing Equipment: Wire Drawing Dies, Drawing Capstan, Frequency Converter, Motor…

Auxiliary Equipment: Wire Pay-Off Stand, Butt Welding Machine, Sharpening Mill…

Technical Parameters of Pulley Type Wire Drawing Machine

| Model | WSL500 Wire Drawing Machine |

|---|---|

| Power | 15kw/drum |

| Wire Inlet Diameter | 6.5mm |

| Wire Outlet Diameter | 1.8mm |

| Drawing Speed | 3.8m/s |

Custom Configuration Options for Wire Drawing Line

To meet the needs of different factories and production, pulley wire drawing machines usually support a variety of custom configurations, including the following aspects:

- Inverter Speed Regulation: Use Variable Frequency Drive (VFD) to achieve step-less adjustment of wire speed, improve stability, and energy-saving effect.

- Number of Drums: Commonly 2 drums, 3 drums, and 4 drums; the more drums, the larger the drawing ratio can be supported, suitable for large changes in wire diameter.

- Drawing Die Specifications: Different specifications of dies can be replaced (such as 6.5-2.0mm, 5.5-3.0mm).

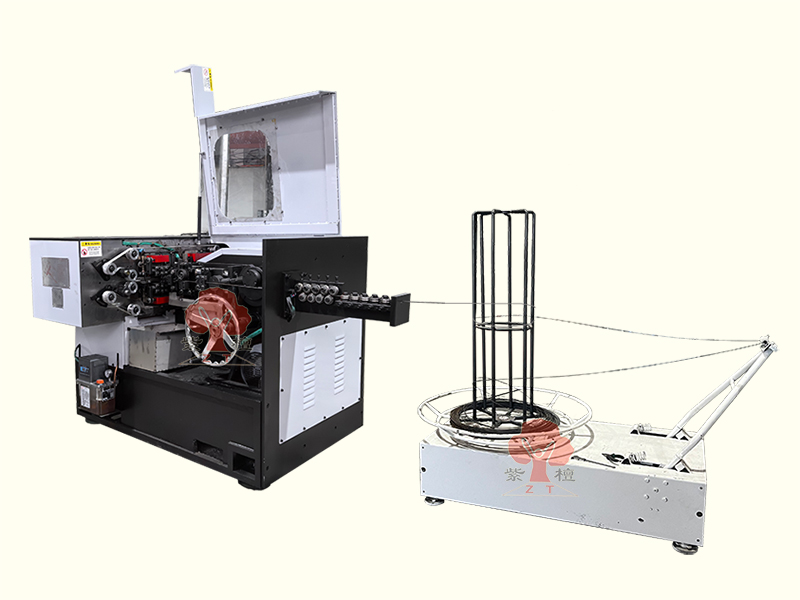

- Wire Collection Method: Supports matching with wire take-up machine.