1-6 Inch Wire Nail Production Line Overview

A wire nail production line is a complete system used to manufacture wire nails from steel wire rods through processes such as wire drawing, nail forming, and polishing. It typically includes the wire drawing machine, nail making machine, and nail polishing machine. This production line is widely used by hardware manufacturers, construction supply factories, and export-oriented enterprises due to the consistent demand for wire nails in global markets.

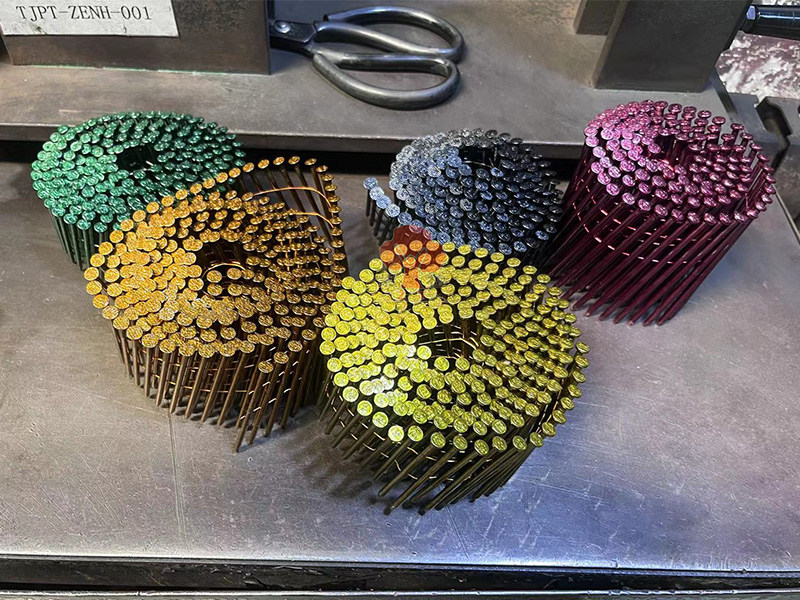

What are Wire Nails?

Wire nails are one of the most common industrial metal fasteners with flat heads, straight shafts, and sharp tips. They are typically made from low-carbon steel wire (Q195, Q235, SAE1008), offering good strength and ductility. Wire nails are widely used in various industries, including building structures, furniture manufacturing, wooden boxes, and pallet packaging…

The raw material of wire nails is usually 6.5mm or 5.5mm steel wire rods, which need to be processed and formed through wire drawing and nail making. For outdoor use, galvanized or stainless steel wire is preferred.

Wire Nail Making Process

Raw Material 6.5mm Wire Rod → Wire Drawing → Cold Drawn Wire → Nail Making → Polishing → Finished Wire Nails

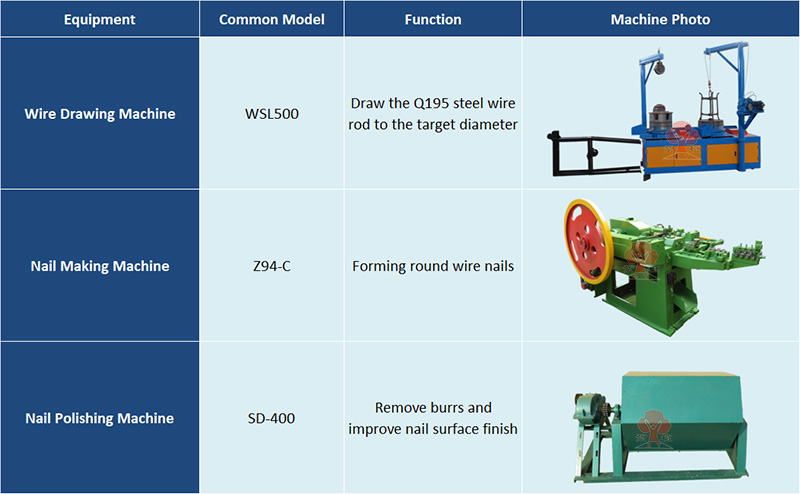

Main Equipment of Wire Nail Production Line

Pulley Type Wire Drawing Machine + Z94-C Series Nail Making Machine + Nail Polishing Machine

Quick-Wear Parts List for Wire Nail Production Line

| No. | Equipment | Spare Parts | Estimated Lifetime | Material | |

|---|---|---|---|---|---|

| 1 | Wire Drawing Machine | Wire drawing die | 15–20 tons | Tungsten carbide | |

| 2 | Nail Making Machine | Nail cutter | 1–2 months | Alloy / Steel | |

| Nail mould/die | ~3 months | Tungsten carbide / HSS | |||

| Pin punch | ~6 months | Tungsten carbide / HSS |

Auxiliary Equipment in Wire Nail Manufacturing (Optional but Recommended)

In addition to the three core equipment – wire drawing machine, nail making machine and polishing machine, the following auxiliary equipment also plays an important role in ensuring production continuity, efficiency and product quality:

Sharpening Mill: Sharpen the steel wire tip to ensure smooth entry into the drawing die and prevent die jam or damage.

Butt Welding Machine: Welds the broken steel wire ends together during wire drawing.

Nail Cutter Grinder: Resharpens the blunt nail cutter for precise nail cutting.