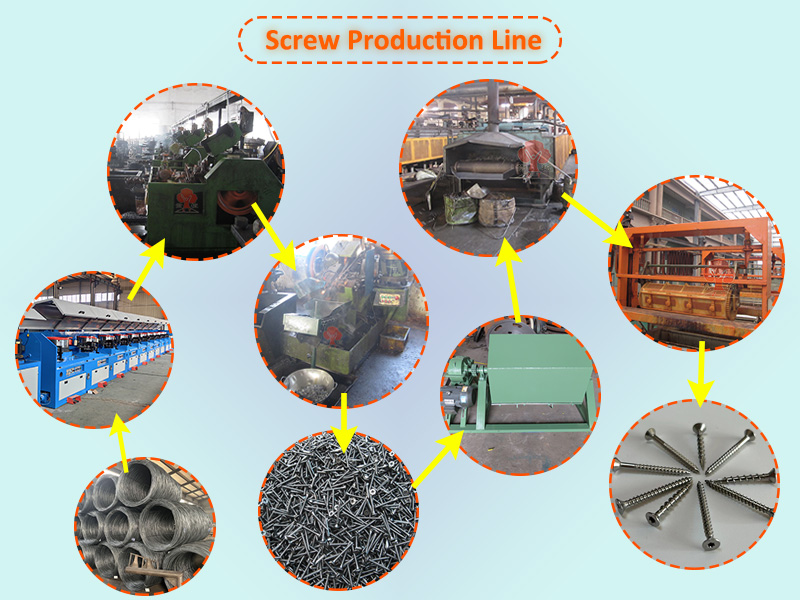

Efficient Screw Production Line: One-Stop Solution from Steel Wire to Finished Screws

Our fully automatic screw production line integrates key processes including wire drawing, cold heading, thread rolling, polishing, heat treatment, and surface galvanization. This production line not only increases production capacity but also ensures that each screw meets international standards in terms of precision, hardness, and appearance, making it suitable for export-grade screw production.

Full Screw Nail Production Process

Wire Rod → Wire Drawing → Cold Heading (Screw Head Forming) → Thread Rolling (Screw Shank and Tip Forming) → Nail Polishing → Heat Treatment (Belt Type Furnace) → Surface Treatment (Zinc Plating) → Final Galvanized Screws

Key Equipment Features of Screw Production Line

High Carbon Wire Drawing Machine:

Adopts multi-pass precision drawing for high-carbon steel wire. Ensures wire diameter stability and surface smoothness, providing high-quality raw material input for screw forming.

Automatic Cold Heading Machine:

It efficiently forms the screw head by cold forging, supports various head types (Such As Phillips Head, Internal Hexagon, External Hexagon, etc.), with fast forming speed and high precision.

High-Speed Thread Rolling Machine:

Rolls precise threads and screw tips without cutting, enhancing the overall strength and thread accuracy of screws.

Polishing Machine:

Removes burrs, oil, and impurities from the screw surface to ensure clean, defect-free surfaces before heat treatment and galvanization.

Belt Furnace (Mesh Belt Heat Treatment Furnace):

It adopts a continuous heating structure, precise temperature control and low energy consumption, so that the screws are evenly quenched and tempered during heat treatment, and improve hardness and toughness.

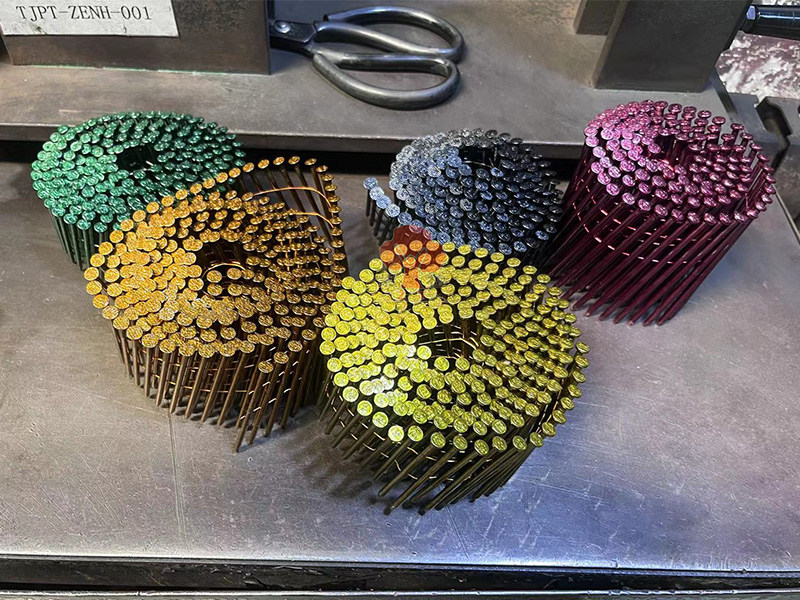

Galvanizing Equipment:

Supports both electro-galvanizing and hot-dip galvanizing. Different anti-corrosion grade solutions can be selected according to customer needs to meet export-grade anti-rust standards.