What are Concrete Nails?

Concrete nails are high-strength nails made from high-carbon steel. They are very hard, thick, and short, with strong penetration ability, allowing them to penetrate directly into concrete, brick walls, and steel.

Raw Materials:

High-Carbon Steel Wire Rods, Such as 45# or 60# Steel.

To ensure both hardness and durability, the wire undergoes annealing, precision drawing, and heat treatment.

Complete Concrete Nail Production Line Process

Raw Material Preparation: Steel Wire Rod

Use Φ6.5mm high-carbon steel with ~0.45–0.60% carbon content.

Primary Wire Drawing (Rough Drawing) – Wire Drawing Machine

Use a wire drawing machine to draw the steel wire to an intermediate diameter, such as Φ2.5mm.

Annealing – Annealing Furnace

The steel wire is heated to 850–900°C in an annealing furnace and then slowly cooled to soften the metal structure and improve ductility.

Secondary Wire Drawing (Fine Drawing) – Wire Drawing Machine

The annealed steel wire is further drawn to the target diameter, such as Φ1.8–2.2mm.

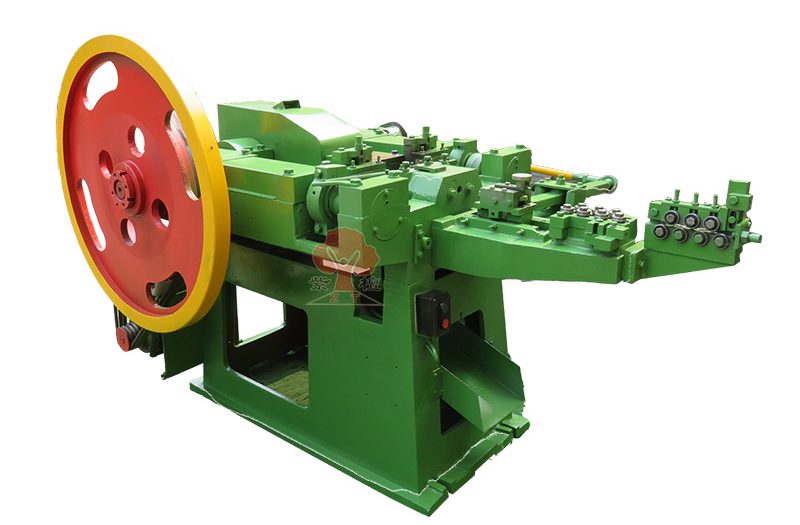

Concrete Nail Manufacturing Machine

The fine-drawn steel wire is fed into a concrete nail making machine, where it undergoes heading and cutting to produce the finished nail.

Polishing – Nail Polishing Machine

Use sawdust, waste oil, paraffin, etc., to smooth the nail’s surface and remove any residual iron burs and imperfections.

Heat Treatment – Belt Furnace

Heat the nails to a high temperature, then rapidly cool them, followed by low-temperature tempering to eliminate brittleness.

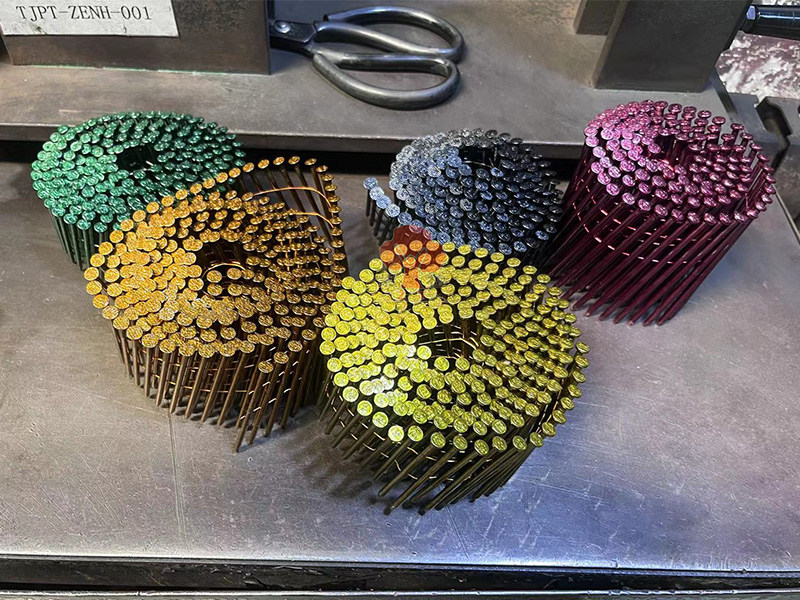

Galvanizing – Electroplating Equipment

To enhance corrosion resistance, the nails are electroplated with zinc. Phosphating or blackening is also available for specific applications.

An efficient concrete nail production line requires not only high-quality equipment but also scientific processes and meticulous management. Whether you’re a new manufacturer or looking to expand production capacity, understanding the technical requirements of every step is crucial to standing out in this competitive market.