Concrete Nail Making Machine – Z94-4C Model

💡 High-Speed Automatic Equipment for Producing Concrete & Cement Nails (25–100mm)

Overview of Z94-4C Concrete Nail Machine

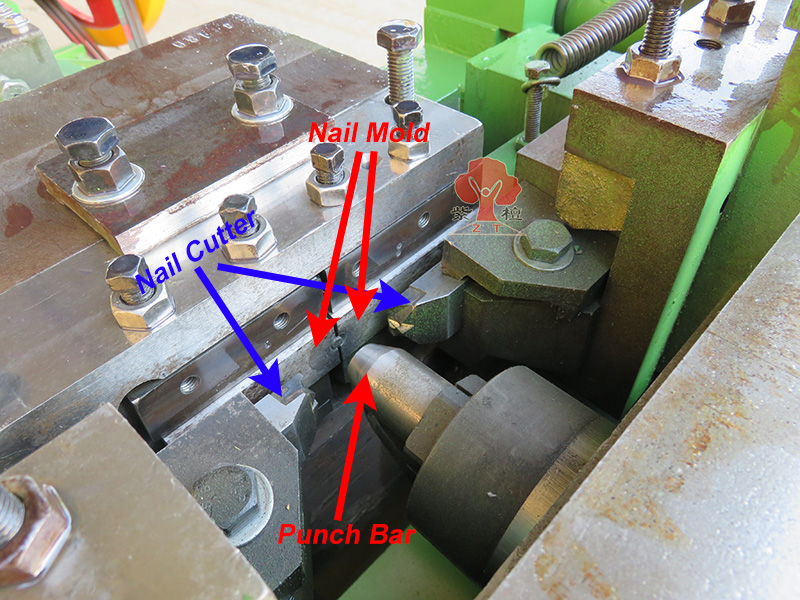

Our Concrete Nail Making Machine, also known as a Cement Nail Machine, is designed for the high-speed production of high-strength concrete nails using high- or medium-carbon steel wire (such as 60# or 55# steel). With durable components and automated control, it ensures precise and efficient manufacturing of cement nail length from 1 to 4 inches (25–100mm).

Whether you are entering the fastener industry or upgrading an existing line, the Z94-4C model delivers the ideal combination of productivity, stability, and cost-effectiveness.

Technical Specifications of Concrete Nail Making Machine

Details of Z94-4C model for cement nail manufacturing

| Item | Specification |

|---|---|

| Model | Z94-4C Concrete Nail Making Machine |

| Nail Length | 25-100 mm (1" – 4") |

| Nail Diameter | 2.0-4.8 mm |

| Production Speed | 220 nails/min |

| Motor Power | 4 kW |

| Machine Dimensions | 2250 × 1500 × 1550 mm |

| Machine Weight | 1850 kg |

| Applicable Material | High / Medium Carbon Steel Wire |

Key Features of the Z94-4C Nail Machine for Cement Nail Production

Benefits of our concrete nail making equipment:

- ⚙️ Fully Automatic Process: Feeding, cutting, and forming in one cycle

- 📏 Flexible Nail Size: Adjustable for different nail lengths and diameters

- 🔩 Quick Die Change: Easy to switch sizes for different production batches

- 💡 Energy Efficient: Low power consumption with a 4kW motor

- 🧱 Rugged Design: Built with heavy-duty steel for long-term industrial use

Recommended Concrete Nail Production Line Setup

For high-efficiency concrete nail manufacturing, we recommend pairing the Z94-4C Concrete Nail Making Machine with the following machines to build a complete production line:

- Wire Drawing Machine – To draw raw steel wire into the required diameter

- Annealing Furnace – To soften drawn wire and improve ductility for the next fine drawing process

- Concrete Nail Making Machine (Z94-4C) – Main equipment for cutting and forming concrete nails

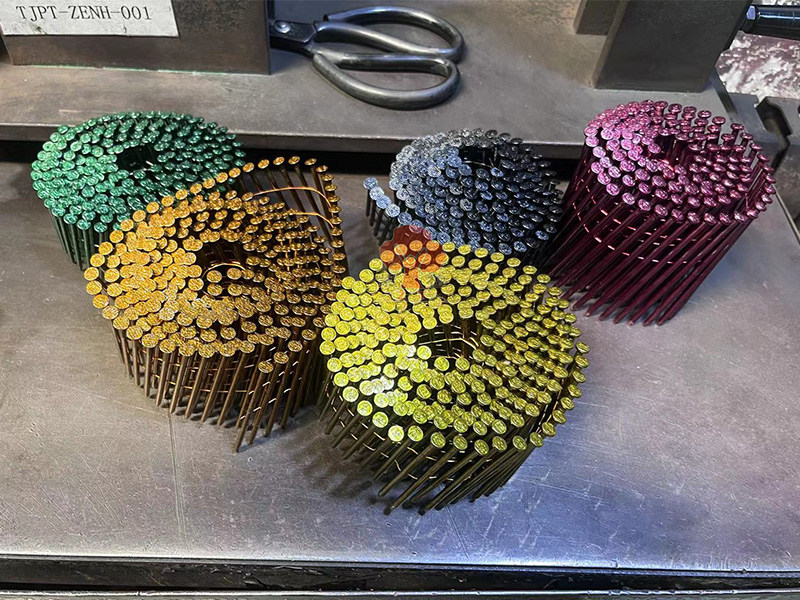

- Nail Polishing Machine – To clean, smooth, and brighten nail surfaces for galvanizing

- Belt Type Heat Treatment Furnace – To harden and temper nails, enhancing strength and durability

- Nail Galvanizing Equipment – Applies a zinc coating to prevent rust and enhance corrosion resistance

- Nail Packaging Machine – For automatic cement nail counting, weighing, and paper box/bagging

✅ We provide full production line design, technical support, and turnkey installation services tailored to your factory needs.

💡 Customizable production lines are available based on your target nail sizes, capacity requirements, and surface treatment needs.

Applications of Concrete & Cement Nails

Concrete and masonry construction

Formwork and wooden frame fastening

Furniture assembly

Hardware manufacturing and export

……