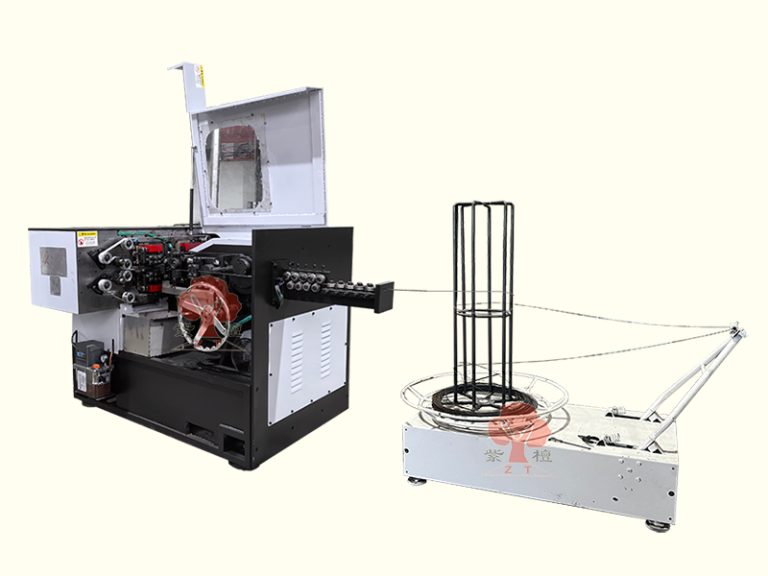

Automatic ZSX-Series High-Speed Nail Making Machine 800 Nails per Min

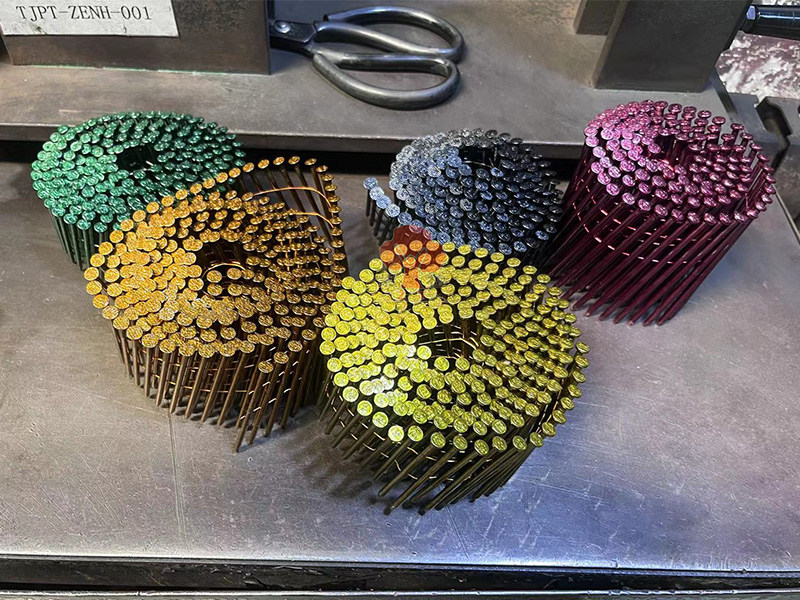

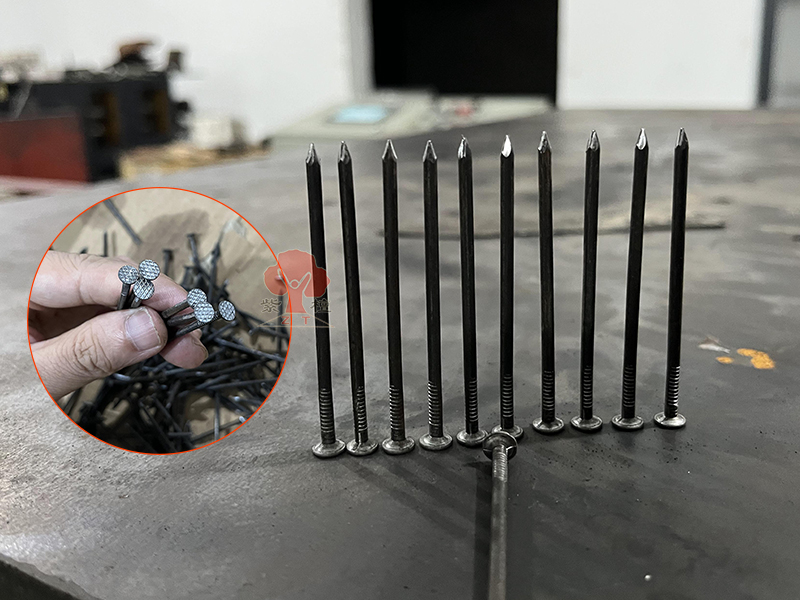

The ZSX-series high-speed nail making machine is a new-generation model designed for producing various types of nails, including wire nails, D-type nails, paper strip nails, concrete nails, and large-cap nails. It operates at speeds of up to 800 nails per minute. The equipment is controlled by PLC and is easy to operate. Eight built-in sensors continuously monitor the working status and automatically shut down the machine in case of faults, ensuring production safety and consistent nail quality.

The machine adopts the same working principle as German Wafios technology. Through synchronized processes such as high-speed wire feeding, cutting, and nail head forming, it ensures uniform nail size and high-precision shaping.

- The first generation: Z94 series (Z94-1C~Z94-5C), Taiwan technology, with a speed of 200-450 nails/minute;

- The second generation: ZSX series (ZSX50~ZSX210), German technology, the speed is increased to 600-800 nails/minute, with higher efficiency and stability.

Parameters of ZSX-Series High-Speed Nail Making Machine 800psc/min

The following are the technical parameters of the main models of the ZS-X series high-speed nail making machine for your quick selection reference:

| Model | Power | Nail Length | Wire Diameter | Speed (psc/min) | Hourly Output | Machine Weight |

|---|---|---|---|---|---|---|

| ZSX50 | 7.7KW | 25-60mm | 1.8-2.6mm | 750-800 | 27-120kg | 2800kg |

| ZSX90 | 7.7KW | 38-90mm | 2.2-3.4mm | 700-750 | 70-230kg | 2800kg |

| ZSX130 | 9.9KW | 70-130mm | 2.8-4.5mm | 550-600 | 120-400kg | 3000kg |

| ZSX150 | 13KW | 80-150mm | 3.5-5.5mm | 450-500 | 200-600kg | 3400kg |

| ZSX210 | 13KW | 100-210mm | 3.5-5.5mm | 380-430 | 220-800kg | 4200kg |

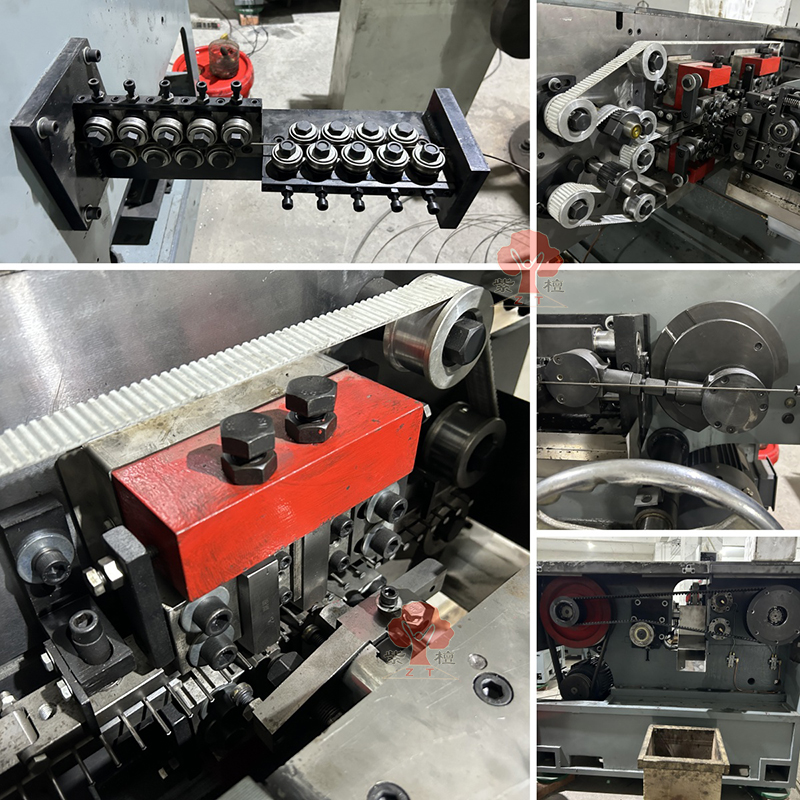

Main Accessories of High-Speed Nail Making Machine

The following is a brief description of commonly used key spare parts:

Nails Transmit Belt: A conventional wearing part, used to transport nails, and cooperate with nail cutters, nail molds, and punches to complete the cutting and forming of nails, with a service life of about 3-5 months.

Main Transmit Belt: The core power transmitting component for connecting the motor and the main shaft, and the service life is generally 1-2 years.

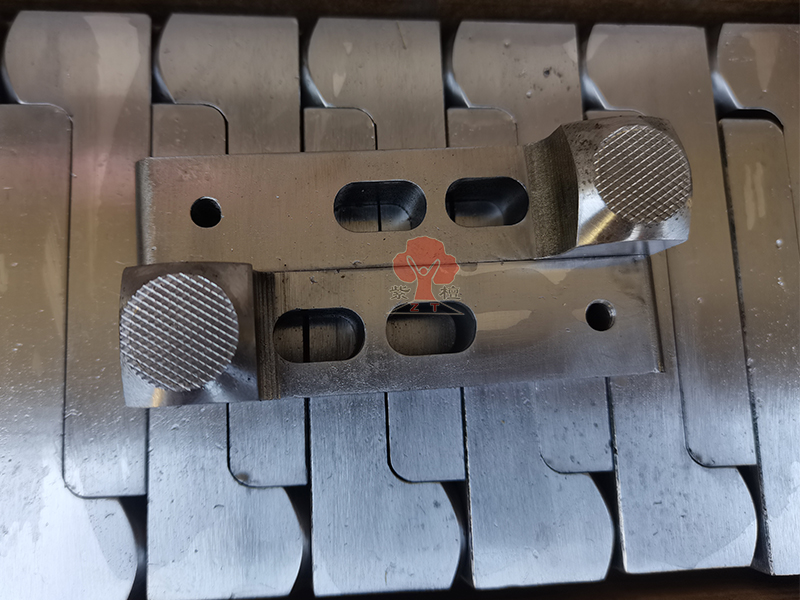

Nail Mould: Provides the power to grasp the steel wire and ensure the forming accuracy of the nail head, with a service life of about 2-3 months.

Nail Cutter: Used to cut the wire, the sharpness of the blade directly affects the quality of the finished nail product, and the service life is generally 1-2 months.

Punch & Pre-punch: Used for nail cap forming, with a service life of about 1-2 months, and needs to be replaced regularly.

These accessories are the core components of the ZSX-series high-speed nail making machine. It is recommended that users regularly check the wear and tear during daily production and keep a stock of commonly used accessories to ensure the continuous operation of the equipment.