Automatic Roofing Nail Making Machine for Umbrella Head Nails – ZT Model

The ZT automatic roofing nail making machine is engineered for the high-speed production of umbrella head galvanized roofing nails. It is suitable for the installation of various building roofing materials, including asbestos tiles, plastic tiles, and metal tiles. The umbrella head roofing nail machine supports nail lengths from 35-100mm and diameters from 2.8-4.5mm, with a production speed of up to 120 nails per minute. Its stable structure, easy operation, and low maintenance make it an efficient choice for building materials and hardware companies for mass production of galvanized tile nails.

✅ It is compatible with common low-carbon steel wire materials, such as the Chinese standard Q195 or the international standard SAE1008, and is also compatible with galvanized steel wire. The finished product offers stable performance, strong tensile strength, and excellent corrosion resistance.

Specification of Roofing Nail Manufacturing Machine

| Model | Umbrella Head Roofing Nail Making Machine |

|---|---|

| Motor Power | 4Kw |

| Nail Length | 35-100mm |

| Nail Diameter | 2.8-4.5mm |

| Production Speed | 120 nails/minute |

| Machine Weight | 2100kg |

| Machine Dimensions | 2350×1512×2000mm |

| Applicable Materials | Q195/ SAE1008 Steel Wire |

How to Make Roofing Nails?

Roofing Nail Production Process Overview

Steel Plate Stamping (for nail caps) + Cold-Drawn Steel Wire Drawing

→ Roofing Nail Caps and Wire Fed into the Roofing Nail Making Machine

→ Formed Roofing Nails

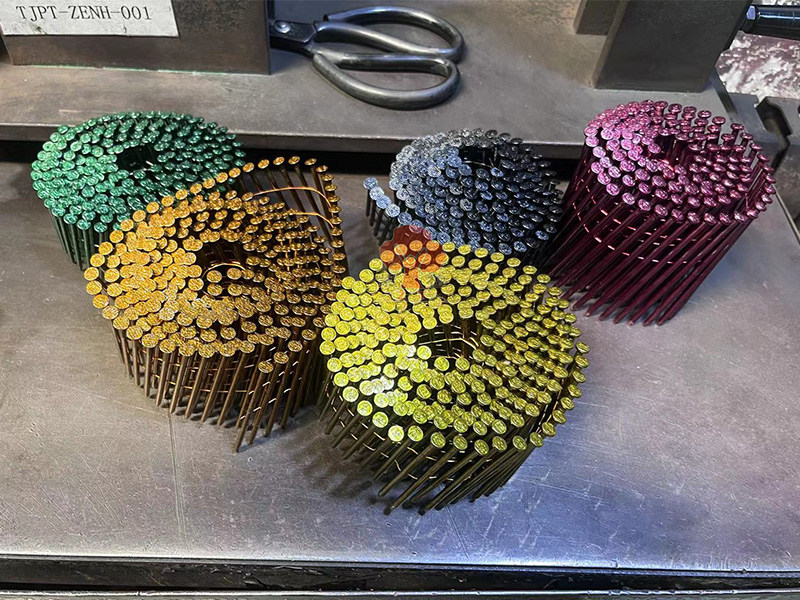

→ Polishing Nails for Surface Smoothness

→ Nail Galvanizing for Rust Protection

→ Finished Galvanized Roofing Nails

Optional Supporting Equipment for Roofing Nail Production Line:

- Roofing Nail Cap Making Machine

- Wire Drawing Machine

- Nail Polishing Machine

- Nail Galvanizing Equipment

👉 All equipment can be purchased individually or as a complete production line, supporting customized solutions.

Umbrella Nail Production Machine Spare Parts

ZT roofing nail machines utilize key components with high wear resistance, suitable for high-frequency, continuous production. The following are the service lives and materials of the main consumable parts:

- Nail Cutter: Lifespan approximately 1–2 months, Made of Alloy Steel

- Nail Die: Lifespan approximately 3 months, Made of Carbide (Tungsten Steel) or High-Speed Steel (HSS)

- Pin Punch: Lifespan approximately 6 months, Made of Carbide (Tungsten Steel) or High-Speed Steel (HSS)

Roofing Nail Making Machine Price – Contact Us for a Quote

Looking for the roofing nail machine price? The cost depends on machine configuration, output capacity, and optional equipment like cap making or galvanizing systems.

To receive an accurate and competitive quote, please contact us directly.

✅ We offer:

Factory-Direct Pricing

Support for Q195 / SAE1008 Wire

Customizable Nail Production Lines

Global Shipping and After-Sales Support

📩 Contact us today to get your personalized quotation and machine details.